What aspects need to be inspected for investment in organic fertilizer production line project

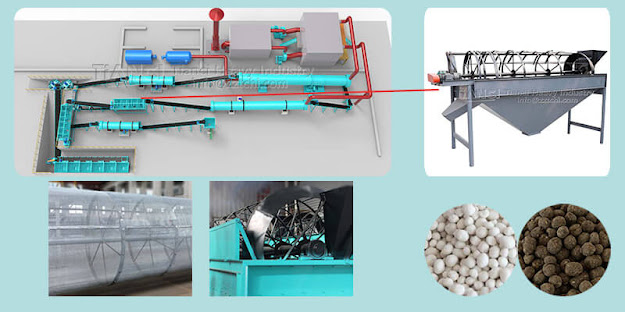

With the increasing attention to the safety of agricultural products, and the increasingly obvious harm of chemical fertilizer to the soil, organic fertilizer has become the widely used fertilizer in agricultural production. What aspects need to be inspected for investment in organic fertilizer production line project? 1. Invest in livestock manure organic fertilizer equipment, control the risk of early investment in organic fertilizer production line project, select appropriate fertilizer equipment manufacturer, and control the investment risk of equipment and construction plant to a certain extent. 2. What are the raw materials for the processing of livestock manure organic fertilizer equipment? What do animal farms raise? There are many pig, duck, chicken, sheep and cattle farmers in various regions. The waste produced by these farming industries is the main raw material for processing organic fertilizer. We should choose the right cooperators according to the market situation ...